Kashmir Silk Carpets

Finest Craftsmanship and Materials

Kashmir silk carpets are highly valued around the world. The Mohabat premium silk carpets are made purely by hand with 100% mulberry silk, which is very rare in the market.

It takes tremendous time and hard work for the Kashmiri artisans to complete one silk carpet from scratch. Each artisan needs to weave more than 82,000 knots in a month, averaging around 3,000 knots a day. Furthermore, to ensure the finest quality for the traditional silk carpets, the Kashmiris insist in hand-cutting the carpets for more precise and intricate patterns. However, this process puts considerable strain on the artisans’ hands, usually causing abrasions after cutting a single carpet. Even though it is difficult to see the difference between the thicknesses of different patterns on the carpets, you will feel the exceptional craftsmanship when you softly touch the unique texture of each carpet.

Painstakingly Long Process

of

Silk Carpet Weaving

The main steps in the process of silk carpet weaving are: designing, weaving, cutting and washing. Out of these four steps, weaving and cutting require the largest amount of time and devotion.

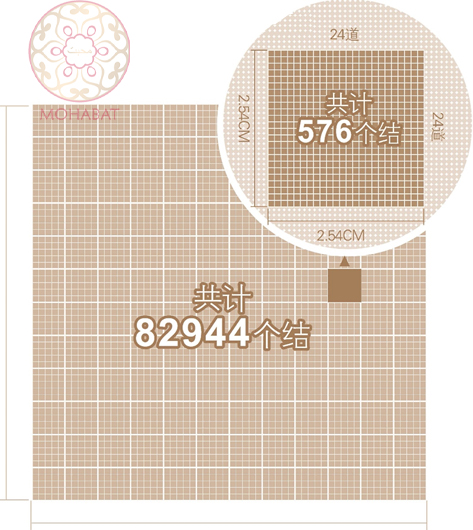

The most common densities for medium to high quality Kashmiri silk carpets are 24×24 threads, 26×26 threads and 30×30 threads per square inch (1 inch equals to 2.54 cm). Take a medium to high quality silk carpet with 24×24 threads for example, the artisans can complete 1 square foot per month in average (1 foot equals to 30.48 cm or 12 inches), and this requires each artisan to tie around 82,000 knots a month, averaging around 3,000 knots a day. Therefore, just weaving a 2.76m x 83m carpet takes 54 months of intensive work.

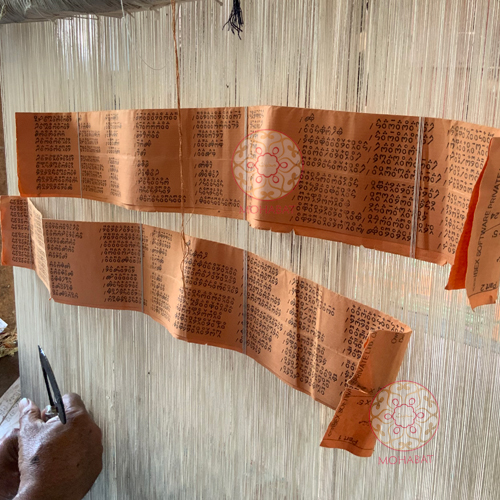

Artisans' Weaving Code

To ensure the highest quality of their traditional silk carpets, the Kashmiri artisans insist in tying each knot and cutting each thread by hands. Traditional Kashmiri artisans are only qualified to produce high-density, large premium carpets after 30 years of age. Under strict standards for carpet density, working on a carpet for long hours heavily strain their eyesight, so they need to develop their skills to the prime before reaching 50 years of age to produce premium carpets with 30×30 threads. The higher density of a silk carpet, the more delicate its patterns and the more grand and magnificent the carpet will be. Equivalently, a silk carpet with higher density also requires a larger working space and more careful knotting, hence significantly increasing the price of the carpet.

An Outstanding Skill

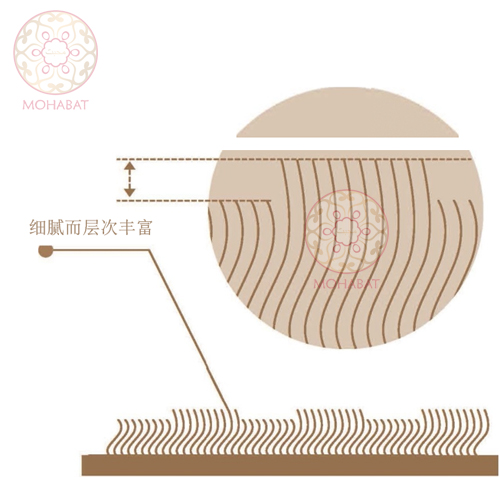

Handwoven carpets are the pride of Kashmiri artisans. With the dominance of industrialization today, most carpet artisans in other parts of the world have adopted machines in their work process, especially for cutting carpets as it requires remarkable accuracy, intensive work, and tremendous strain on both the mind and eyes. According to the artisans, their hands will get abrasions after cutting a single carpet. However, the Kashmiri artisans insist in hand-cutting each carpet in pursuit of perfection, not only because hand-cutting can retain the thickness of the carpet, but more importantly, it can distinguish the different patterns and texture of the carpet, resulting in more delicate and elaborate patterns. Even though it is difficult to see the difference between the thicknesses of different patterns on the carpets, you will feel the exceptional craftsmanship when you softly touch the unique texture of each carpet.

The design of the silk carpets is also worth noting. Each family of carpet artisans has a special carpet blueprint that stays solely within the family, and has been further developed and improved by each generation of artisans in the family. Therefore, the carpets produced by each Kashmiri family are different, and because it is impossible for each generation to complete every single blueprint passed down by their ancestors, it is unlikely to find two identical carpets at the same time.